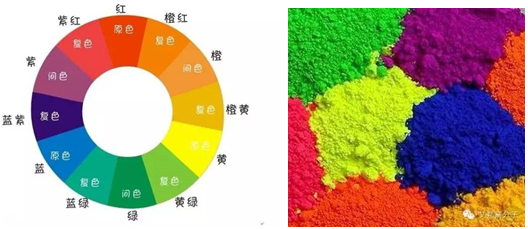

Marka iftiinku ku dhaqmo alaabada balaastiigga ah, qayb ka mid ah iftiinka ayaa ka soo ifbaxaya dusha sare ee alaabta si ay u soo saarto dhalaal, qaybta kale ee iftiinka ayaa dib loo soo celiyaa oo loo gudbiyaa gudaha gudaha caagga.Marka aad la kulanto qaybaha midabka midabka, milicsiga, dib-u-celinta iyo gudbinta ayaa soo noqnoqda, midabka la soo bandhigayna waa qaybaha midabka.Midabka muuqda.

Hababka midabaynta caaga ah ee sida caadiga ah loo isticmaalo waa: midabaynta qalalan, midabaynta koollada (koollada midabka) midabaynta, midabka masterbatch midabaynta.

1. Midabaynta qalalan

Habka isku dhafka iyo midabaynta tooska ah ee toner (midab ama midabyo) oo lagu daro qadarka ku habboon ee lagu daro budada iyo alaabta ceeriin ee caag ah ayaa loo yaqaan midabaynta qalalan.

Faa'iidooyinka midabaynta qalalan ayaa ah kala-bax wanaagsan iyo qiimo jaban.Waxaa loo qeexi karaa si sabab la'aan ah iyadoo loo eegayo baahida, iyo diyaarinta waa mid aad u habboon.Waxay badbaadisaa isticmaalka tamarta iyo agabka agabka ee farsamaynta midabaynta sida masterbatches-ka midabka iyo koollada midabka, markaa kharashku waa yar yahay, iibsada iyo iibiyayaashu uma baahna inay isticmaalaan.Waxaa lagu xaddiday qaddarka;Khasaaraha ayaa ah in midabku uu boodh duulo oo uu wasakheeyo inta lagu jiro gaadiidka, kaydinta, miisaanka iyo isku dhafka, taas oo saamayn doonta deegaanka shaqada iyo caafimaadka hawl-wadeennada.

2. Ku dheji midabaynta (koollada midabka) midabaynta

Habka midabaynta, midabaynta inta badan waxaa lagu qasaa kaaliyaha midabaynta dareeraha ah (plasticizer ama resin) oo lagu shubo koollo, ka dibna si siman ayaa loogu daraa caag, sida midabka midabka dhaldhalaalka, rinjiga, iwm.

Faa'iidada midabaynta midabaynta (midabka midabka) midabaynta ayaa ah in saameynta kala-baxa ay wanaagsan tahay, wasakhowga boodhkana lama samayn doono;qasaaraha ayaa ah in cadadka midabaynta aysan sahlanayn in la xisaabiyo qiimuhuna uu sareeyo.

3. Masterbatch midabaynta

Marka la diyaarinayo masterbatches midabka, pigments midabka u qalma ayaa inta badan la diyaariyaa marka hore, ka dibna pigments waxaa lagu daraa galay sidaha masterbatch midabka sida waafaqsan saamiga formula.Unugyada si buuxda ayaa loo isku daray, ka dibna laga dhigayaa qaybo la mid ah xajmiyada xabagta, kuwaas oo markaa loo isticmaalo qalabaynta si loo sameeyo badeecooyin caag ah.Marka la isticmaalo, kaliya qayb yar (1% ~ 4%) ayaa loo baahan yahay in lagu daro resin midab leh si loo gaaro ujeedada midabaynta.

Marka la barbardhigo midabaynta qalalan, midabaynta masterbatch waxay leedahay faa'iidooyinka soo socda ee muuqda: hagaajinta wasakheynta deegaanka ee ay keento toner duulaya, isbeddel sahlan oo midab leh inta lagu jiro isticmaalka, ma jiro nadiifin gaar ah oo ka mid ah hopper extruder, iyo qaacidada xasilloon Waxay leedahay waxqabad xoog leh waxayna hubin kartaa in midabka labada qaybood ee masterbatches midabka ee astaanta isku midka ah ayaa weli ah mid deggan.Dhibaatada midabaynta masterbatch waa in qiimaha midabaynta uu sarreeyo iyo tirada diyaargarowga ma aha mid dabacsan.Intaa waxaa dheer, toners pearlescent, budada fluorescent, budada iftiinka iyo toneryada kale ayaa laga sameeyaa bacaha midabada ka dibna loo isticmaalo midabaynta balaastikada.Marka la barbar dhigo isku dhafka tooska ah ee balaastikada midabaynta, saamaynta (sida gloss, iwm.) waxaa wiiqay ilaa 10%, iyo alaabada qaabeynta duritaanka sidoo kale waxay u nugul yihiin xadhkaha socodka.Xariijimo iyo tolmo.

tixraacyo

[1] Zhong Shuheng.Halabuurka Midabka.Beijing: Guriga Daabacaada Farshaxanka Shiinaha, 1994.

[2] Song Zhuoyi et al.Walxaha ceeriin caagga ah iyo waxyaabaha lagu daro.Beijing: Guriga Daabacaada Suugaanta Sayniska iyo Tignoolajiyada, 2006. [3] Wu Lifeng et al.Buugga Isticmaalaha Masterbatch.Beijing: Saxaafadda Warshadaha Kiimikada, 2011.

[4] Yu Wenjie iyo al.Farsamada Naqshadeynta Waxyaalaha Caagagga ah iyo FarsamayntaQormada 3aad.Beijing: Warshadaha Kiimikada Press, 2010. [5] Wu Lifeng.Naqshadeynta Midabaynta Caaga ah.Qormada 2aad.Beijing: Saxaafadda Warshadaha Kiimikada, 2009

Waqtiga boostada: Abriil-09-2022